The New Year continues to provide you with paper food packaging solutions

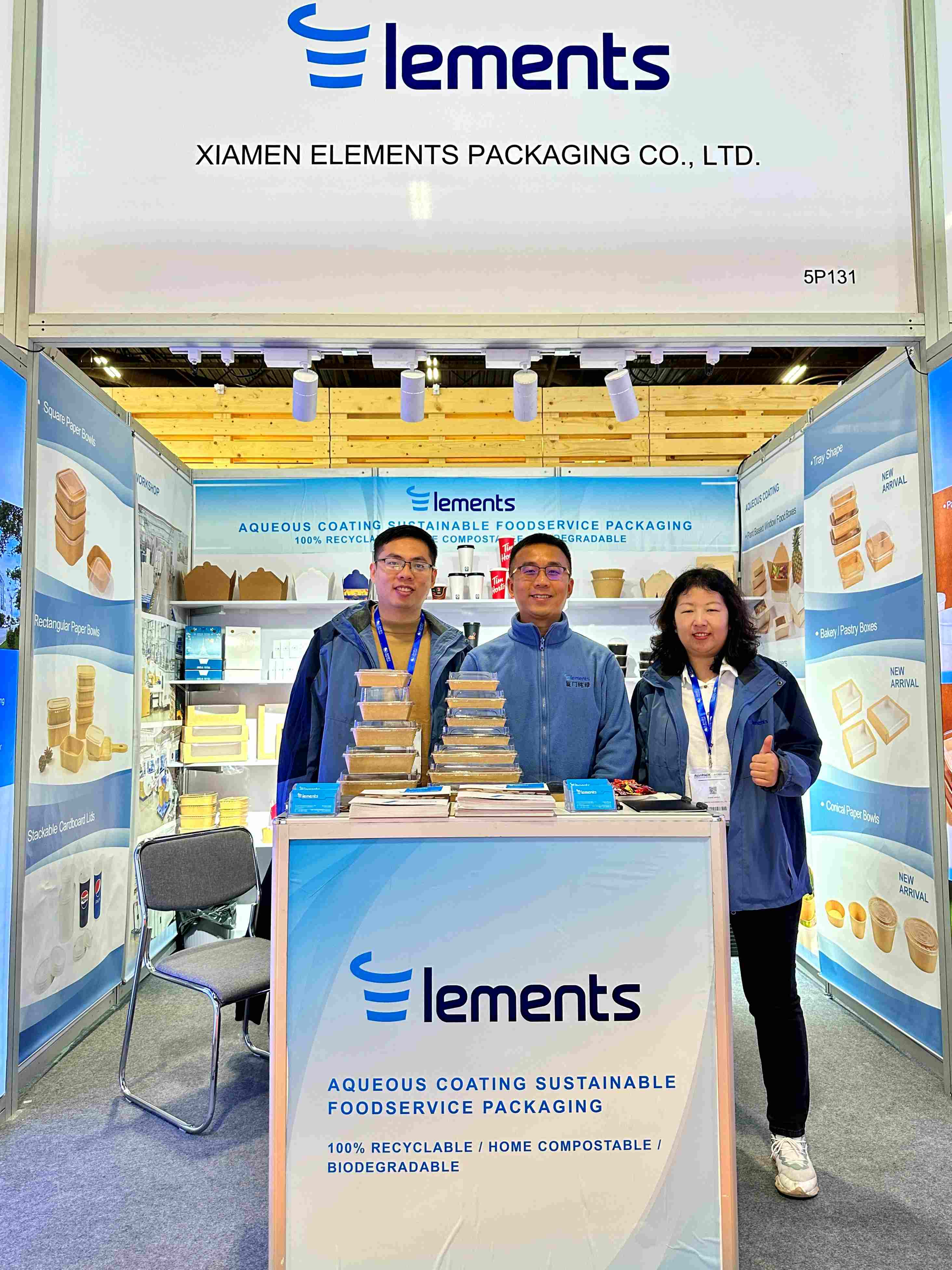

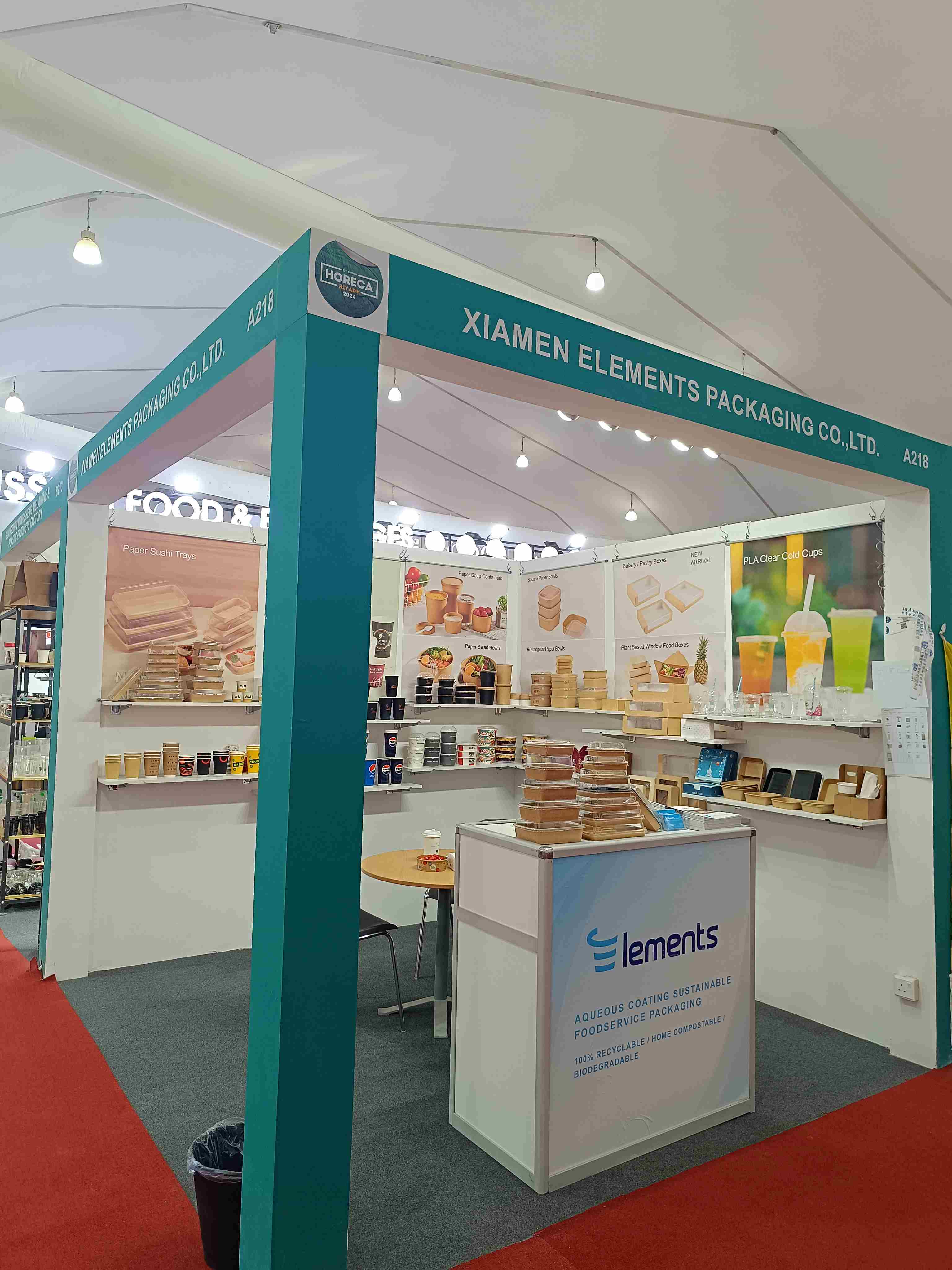

The New Year has begun and we look back at the three extraordinary expos we attended in October and November of last year and it has been a very fruitful journey. We participated in the prestigious Canton Fair in Guangzhou, the splendid ALL4PACK exhibition in Paris, and the captivating SAUDI HORECA event in the enchanting Saudi Arabia.

We firmly believe in the values of sustainability and green environmental practices, recognizing our integral role in cultivating a harmonious coexistence with our planet. Our dedication to creating a more beautiful earth through eco-friendly food packaging solutions has been the driving force behind our success.

These forthcoming exhibitions will serve as a platform for us to unveil even more superior food packaging solutions, tailored specifically to meet your needs.

In a world brimming with possibilities, we strive to be your unwavering partner in progress, constantly pushing boundaries and evolving to exceed your expectations. Together, let us embark on this fascinating journey towards a future where innovation and sustainability reign supreme, encapsulating the essence of our shared aspirations.