In modern food packaging production lines, the efficiency and quality of the cutting process directly affect the overall production rhythm and product appearance. As a specially designed cutting tool, the serrated blade demonstrates outstanding performance in the food packaging field due to its unique structural advantages. Today, we will take an in-depth look at the application features, core advantages, and key technical performance of serrated blades in the food packaging industry.

What is a serrated blade?

A serrated blade, also known as a saw-tooth blade, is a specialized cutting tool with a continuously serrated edge design. Compared with a straight-edge blade, its edge displays a regularly spaced saw-tooth pattern, which offers significant advantages when cutting flexible, composite, or somewhat elastic packaging materials. Serrated blades are typically made of high-hardness stainless steel or special alloy steel, balancing sharpness, wear resistance, and corrosion resistance.

Main applications of serrated blades in food packaging

· Film slitting and bag making: Used for continuous slitting of materials such as PE, PP, and composite films. The serrated design effectively prevents film misalignment and sticking.

·Cutting of biscuits, pastries, and other shaped foods: Achieves quick separation while maintaining the product’s shape and reducing debris.

· Easy-tear notch processing on packaging bags: Pre-designing serrated tear lines on packaging bags enhances user experience.

·Frozen food cutting: Suitable for cutting frozen dough and frozen foods, with the serrated structure reducing material sticking to the blade.

·Cardboard and blister pack slitting: Used for cutting paper-based and aluminum-plastic blister packaging, providing neat cuts that are resistant to deformation.

Five core advantages of serrated blades

1. Strong anti-stick and anti-misalignment capability

The serrated edge has relatively small contact areas with the material during cutting, making it especially suitable for materials with higher stickiness (such as sugar-containing foods or frozen food packaging), effectively reducing material adhesion to the blade. Additionally, the serrated structure helps guide the material, preventing misalignment during high-speed cutting of films or flexible materials.

2. Low cutting resistance and energy consumption

Compared with straight-edge cutting, serrated blades use a "point-contact progressive cutting" principle, requiring less cutting force, reducing the operating load on equipment, conserving energy, and extending the life of transmission components.

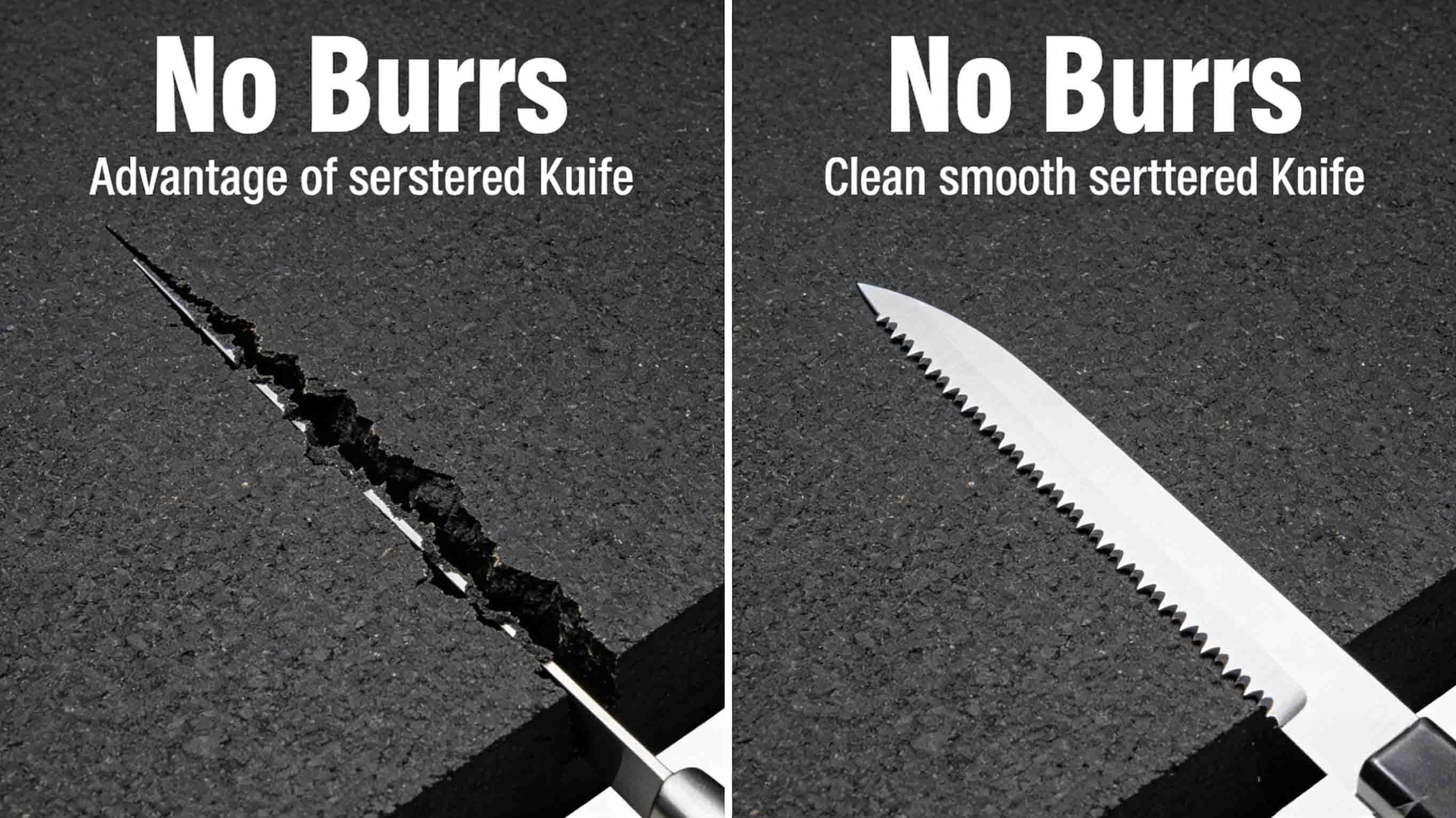

3. Neat cuts with minimal fraying

For materials prone to fraying, such as non-woven fabrics and composite films, serrated blades provide clean, precise cuts. The resulting edges are smooth and aesthetically pleasing, improving the quality of the finished packaging products.

4. Longer service life

By optimizing the serration angles and spacing, wear during cutting is distributed more evenly, slowing down blade dulling. Compared with straight-edge blades, the service life can be extended by approximately 30%-50%, reducing the frequency of blade replacement and lowering production costs.

5. Adapting to High-Speed Continuous Operations

The structural characteristics of the toothed blade allow it to maintain stable cutting performance at high speeds, making it ideal for modern high-speed packaging production lines and helping to improve overall production efficiency.

Key Performance Indicators Analysis

· Tooth Design: Parameters such as tooth height, pitch, and angle need to be optimized according to material thickness, elasticity, and cutting speed.

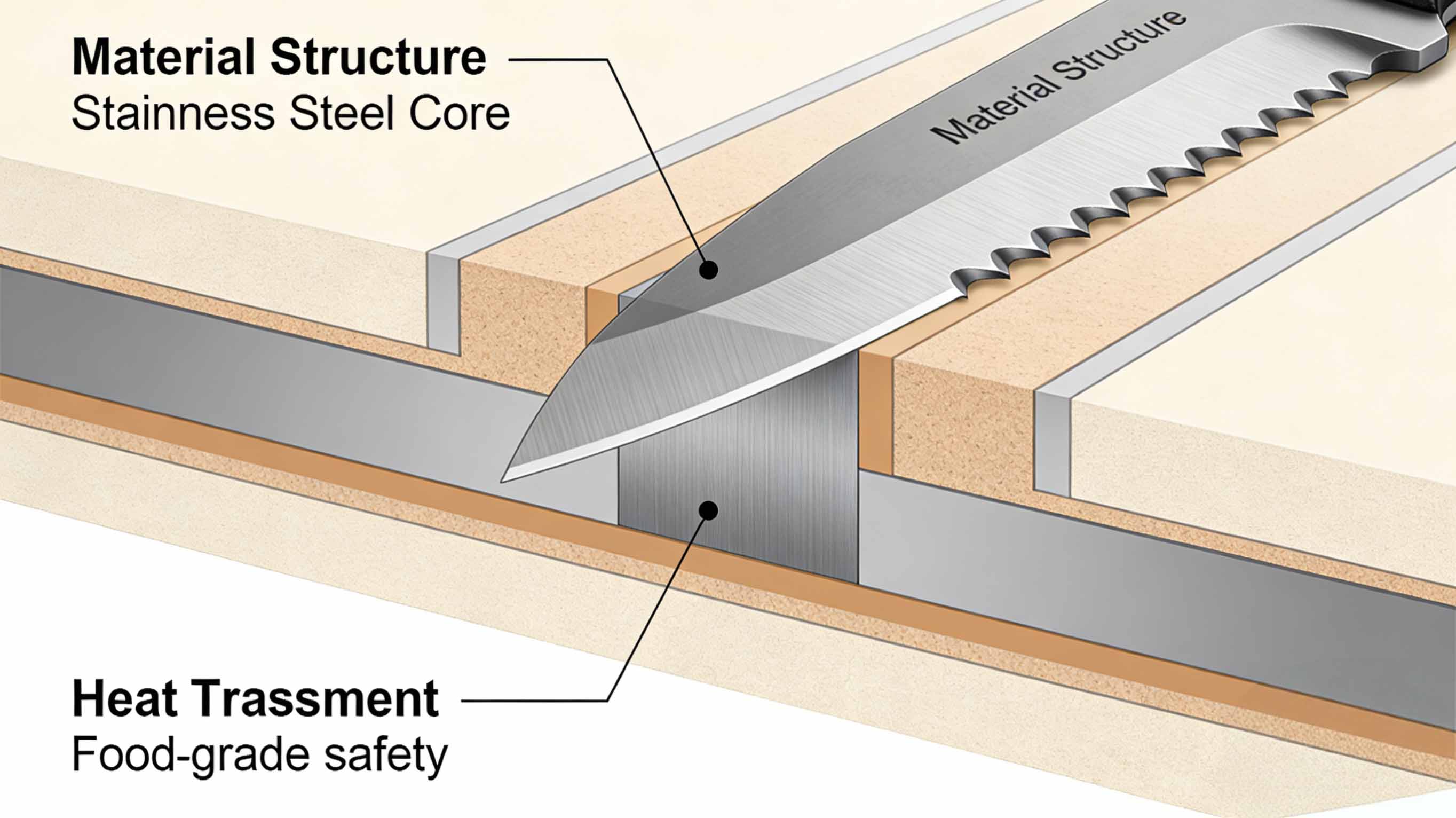

· Material Selection: The food packaging industry has very high hygiene requirements; blade materials typically include 9CrSi, Cr12MoV, stainless steel, etc., and must comply with safety standards for materials in contact with food.

· Balance of Hardness and Toughness: The cutting edge hardness is usually maintained between HRC55-62 to ensure wear resistance while avoiding chipping.

· Surface Treatment Process: Surface reinforcement treatments such as titanium coating and nitriding can further enhance corrosion and wear resistance.

· Installation and Calibration Accuracy: The installation angle and tension of the toothed blade directly affect cutting performance and must be precisely adjusted according to equipment requirements.

What Can We Offer to the Food Packaging Industry?

Mingbai Machinery Tool Technology Co., Ltd. has been deeply engaged in blade R&D and manufacturing for many years and has rich experience in custom solutions for food packaging toothed blades. We can provide full-process customized services—including tooth design, material selection, heat treatment, and precision grinding—based on customers’equipment models, packaging material characteristics, production speed, and specific requirements. This ensures that each toothed blade delivers stable and excellent performance in actual production.

If you are looking for high-performance toothed blade solutions for food packaging or need to optimize and upgrade your existing blades, contact Mingbai Technology. We will provide professional technical support and reliable blade products to help your production line operate efficiently and stably.