What Is Special About Runk Brand Rare Beauty Cosmetic Packaging Tubes?

In the world of modern cosmetics, packaging is no longer just a container — it is an experience, a message, and a direct reflection of brand value. Runk’s Rare Beauty Cosmetic Packaging Tubes are designed with this philosophy in mind, offering a premium combination of aesthetic appeal, material innovation, and functional performance. From their luxurious metallic appearance to the carefully engineered structure, these tubes elevate every product they hold.

1. Premium Metallic Aesthetic for High-End Brands

One of the defining characteristics of Runk’s cosmetic tubes is their distinctive metallic finish. Available in elegant gold and silver options, these tubes instantly communicate luxury and refinement. The high-gloss surface creates a mirror-like shine that enhances shelf presence, making them ideal for premium skincare, BB/CC creams, hand creams, and specialty beauty products.

Each tube is fully customizable, allowing brands to apply their own logo or artwork with exceptional clarity. The reflective finish not only enhances branding visibility but also adds a modern and sophisticated touch that consumers instantly recognize and trust.

2. High-Performance ABL Structure With ABS Decorative Cap

Runk’s Rare Beauty Packaging Tubes are manufactured using an ABL (Aluminum Barrier Laminate) structure, which provides superior product protection. The ABL layer ensures excellent barrier properties against light, oxygen, and moisture — essential for maintaining the stability and freshness of sensitive cosmetic formulas.

The tubes are paired with an exquisitely designed ABS decorative cap, shaped with a jewelry-like profile and metallic sheen. This unique closure design is not only visually striking but also ensures reliable sealing performance. The combination of ABL and ABS materials results in packaging that is both technically advanced and visually premium.

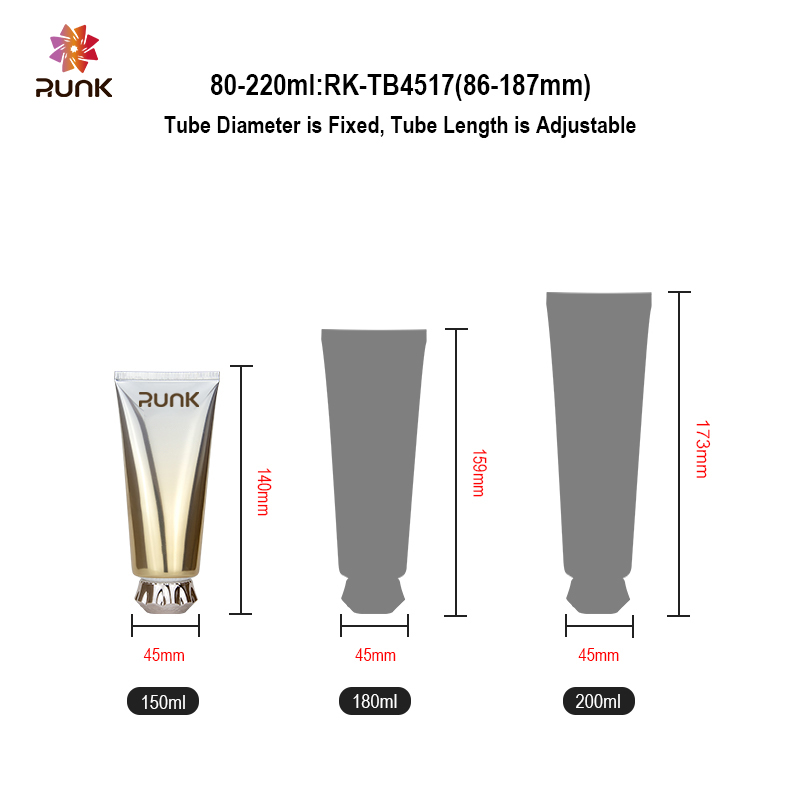

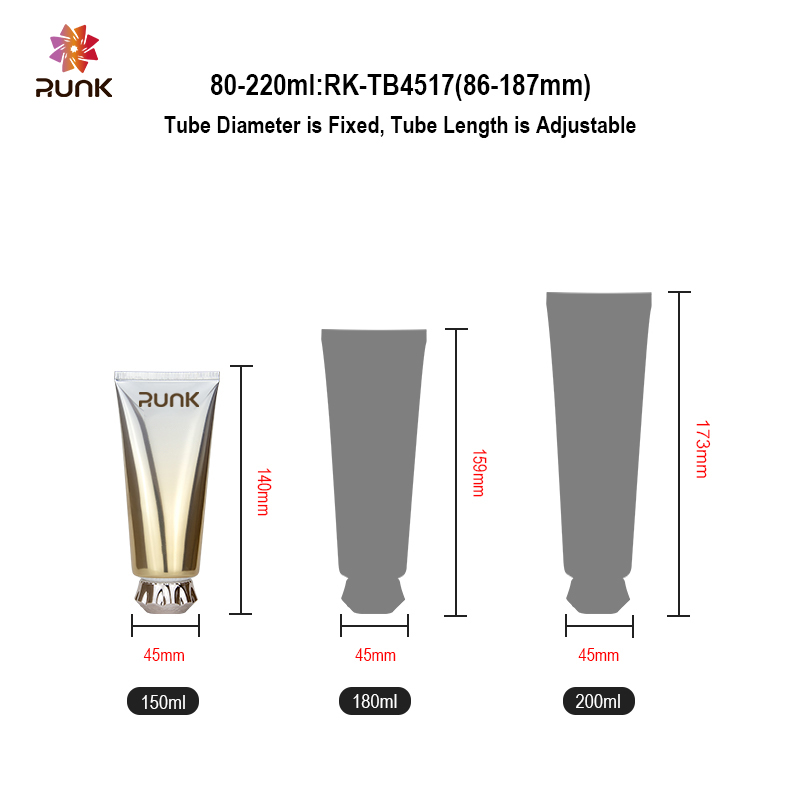

3. Adjustable Length for Multiple Capacities

To support global brands with flexible product planning, Runk provides these tubes in adjustable lengths while maintaining a fixed diameter of 45mm. This allows customers to select a variety of capacities ranging from 80 ml to 220 ml.

Standard examples include:

150 ml – 140 mm tube height

180 ml – 159 mm tube height

200 ml – 173 mm tube height

This modular sizing system offers efficient production, reduced tooling limitations, and seamless scalability for different product lines.

4. Enhanced Consumer Experience Through Thoughtful Design

From the smooth dispensing function to the ergonomic tube shape, every detail supports user-friendly performance. The wide opening ensures easy filling during production and smooth product flow during consumer use. The decorative cap provides comfortable grip and precise opening/closing, giving the end-user a pleasant and satisfying daily experience.

The lightweight yet durable construction also makes these tubes travel-friendly and impact-resistant.

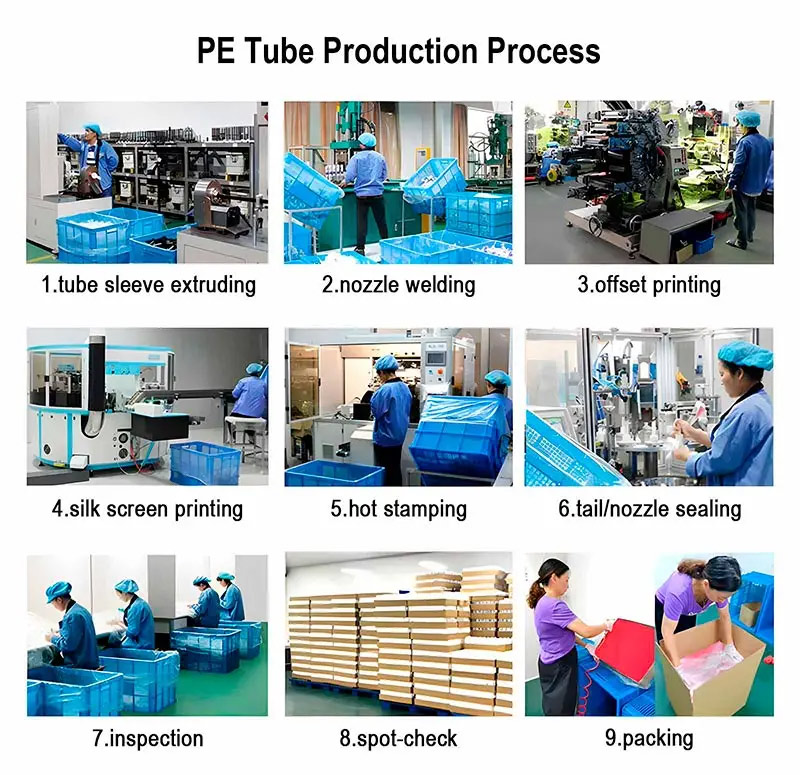

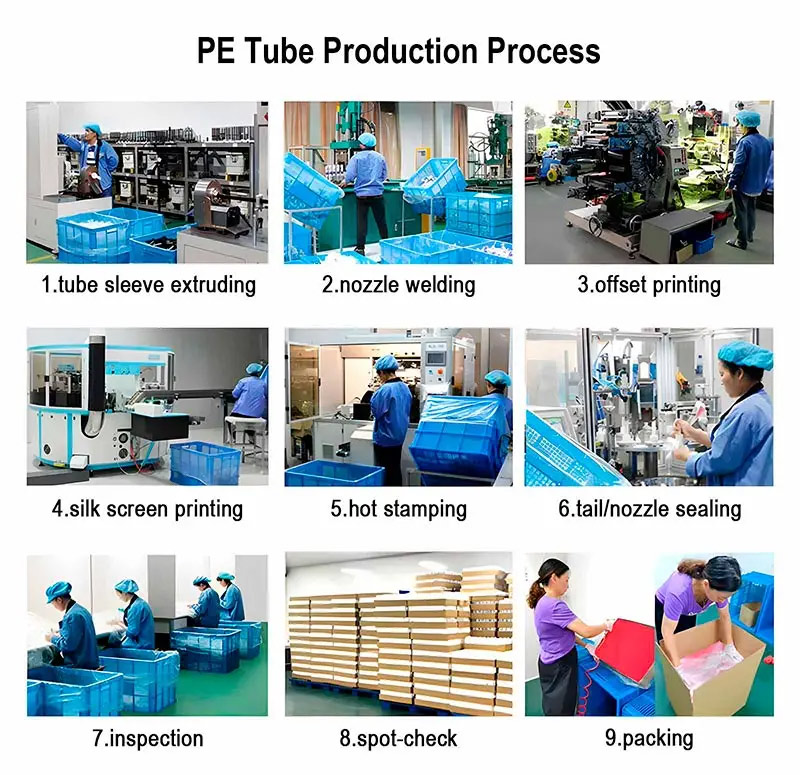

5. A Transparent and Reliable Production Process

Runk ensures consistent quality through a structured and traceable manufacturing workflow, which includes:

♣ Sample Test – evaluating structure, decoration, and formula compatibility

♣ Cost Confirmation – finalizing budgets and specifications

♣ PPS & RB Approval – confirming pre-production samples and artwork

♣ Bulk Production – executing high-volume manufacturing

♣ Inspection – performing rigorous quality checks

♣ Shipping – preparing and dispatching the finished goods

This systematic process guarantees stable quality, accurate delivery, and high customer satisfaction.

Conclusion

Runk’s Rare Beauty Cosmetic Packaging Tubes stand out in the market because they combine luxury aesthetics, material innovation, functional precision, and flexible customization. Whether you are launching a new product line or upgrading existing packaging, these tubes offer a high-end presentation that elevates your brand and enhances the consumer experience.

If you are looking for eye-catching, durable, and customizable cosmetic tube packaging, Runk cosmetic packaging supplier provides the reliability and creativity your brand deserves.