Innovative Cosmetic Packaging Solutions from Runk: Elevating the Beauty Experience

At Runk we take pride in offering high-quality cosmetic packaging solutions that meet both aesthetic and functional needs. Our packaging is designed to ensure that every beauty product is beautifully presented while maintaining its integrity.

Sleek and Practical Designs

Our cosmetic tubes, such as the ones featured in the images, reflect modern elegance with a minimalistic touch. Available in various sizes, our tubes are perfect for a range of cosmetic products, including creams, lotions, and serums. These tubes are crafted with premium materials to provide durability and a refined finish, ensuring that your brand stands out.

Key Features of Runk Cosmetic Tubes

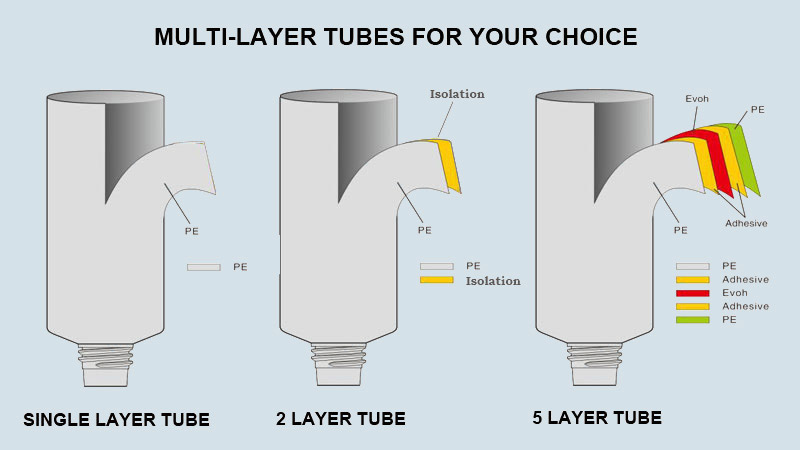

1.Premium Materials

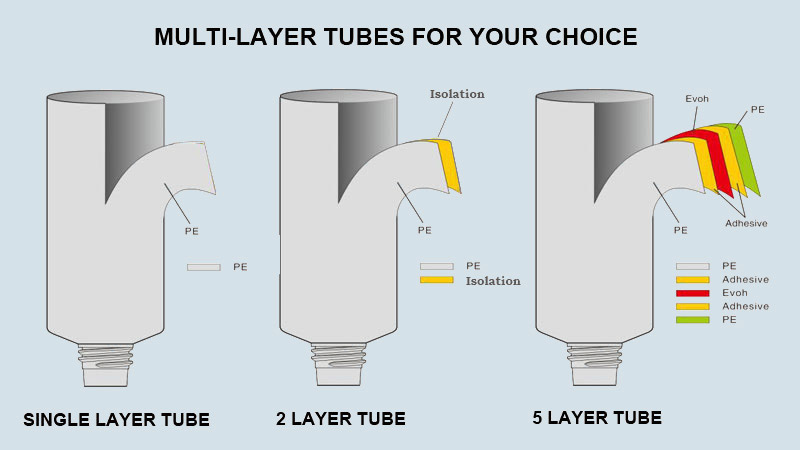

Runk tubes are made with superior materials like 5 layers of PE and PP, offering a sleek finish while ensuring the protection of the product inside. This combination delivers flexibility and durability, ensuring that the packaging withstands everyday handling without compromising the product's integrity.

2.Premium Materials

Runk tubes are made with superior materials like 5 layers of PE and PP, offering a sleek finish while ensuring the protection of the product inside. This combination delivers flexibility and durability, ensuring that the packaging withstands everyday handling without compromising the product's integrity.

3.Easy-to-Use Packaging

Designed with user convenience in mind, our tubes feature easy dispensing mechanisms. The smooth application from the pump or twist cap ensures that your consumers have a hassle-free experience. The compact design also makes them perfect for both home use and travel, adding to the convenience.

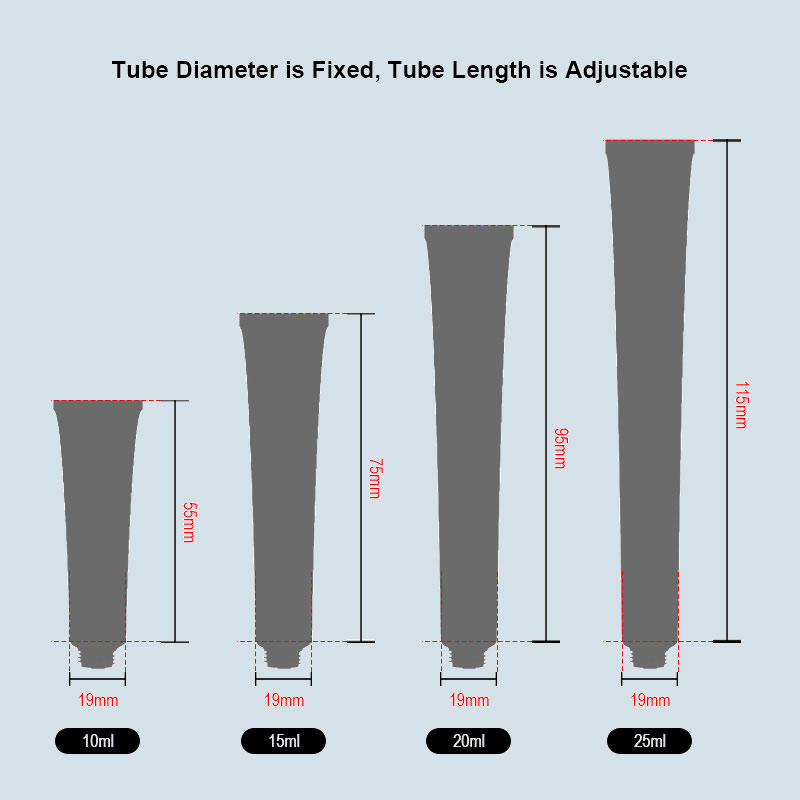

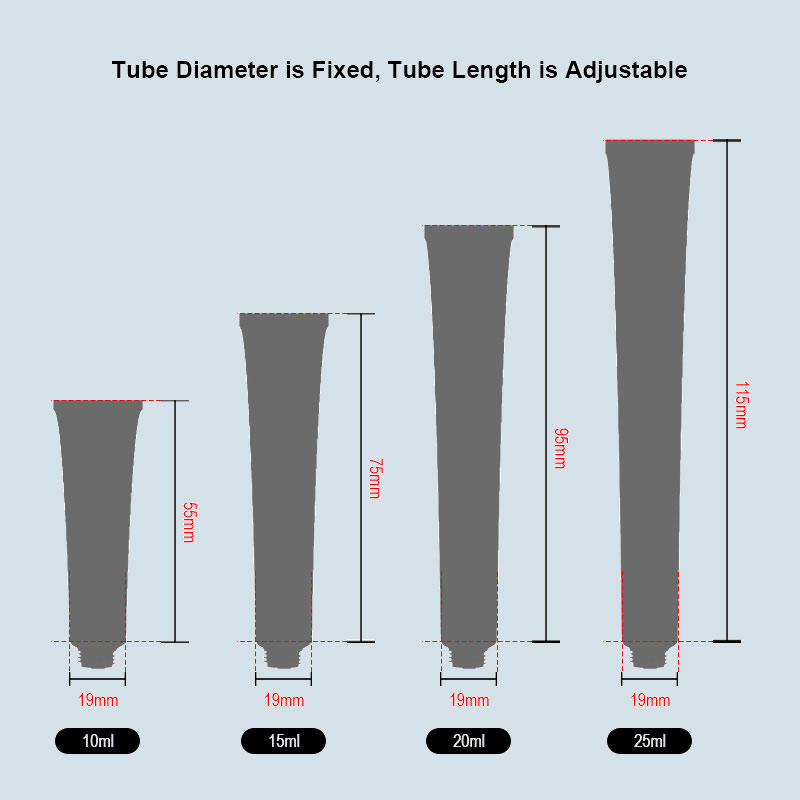

4.Customizable Sizes

Our packaging is versatile, with customizable sizes ranging from 3ml to 450ml. This makes it easy to tailor the packaging to meet the unique needs of your product. The adjustable tube lengths provide flexibility in packaging design, making it adaptable for both small and large batches.

5.Eco-Friendly Options

We are committed to sustainability. Our packaging is designed with eco-friendly materials, helping reduce the environmental impact without sacrificing quality or performance.

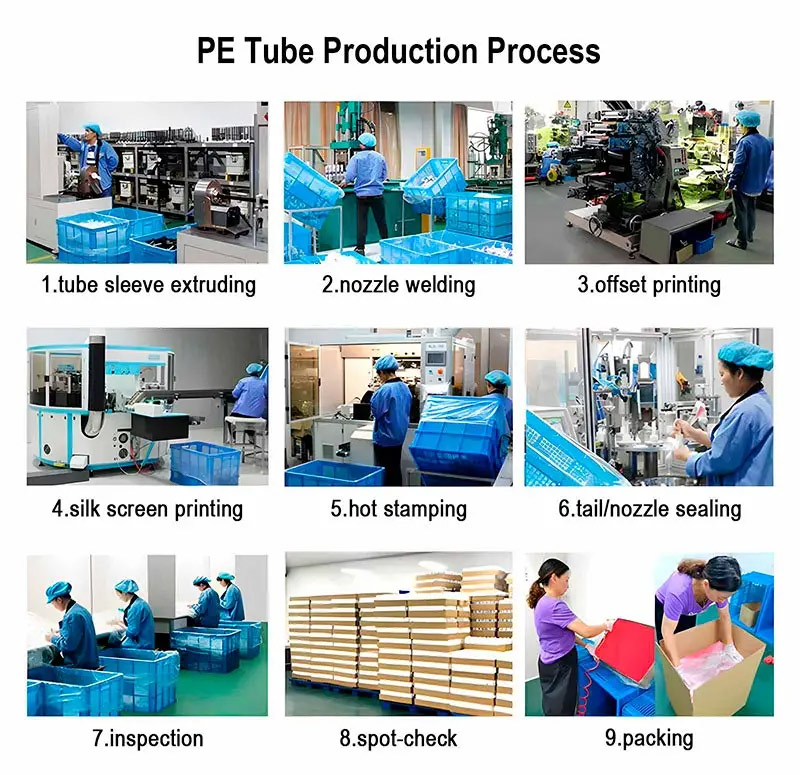

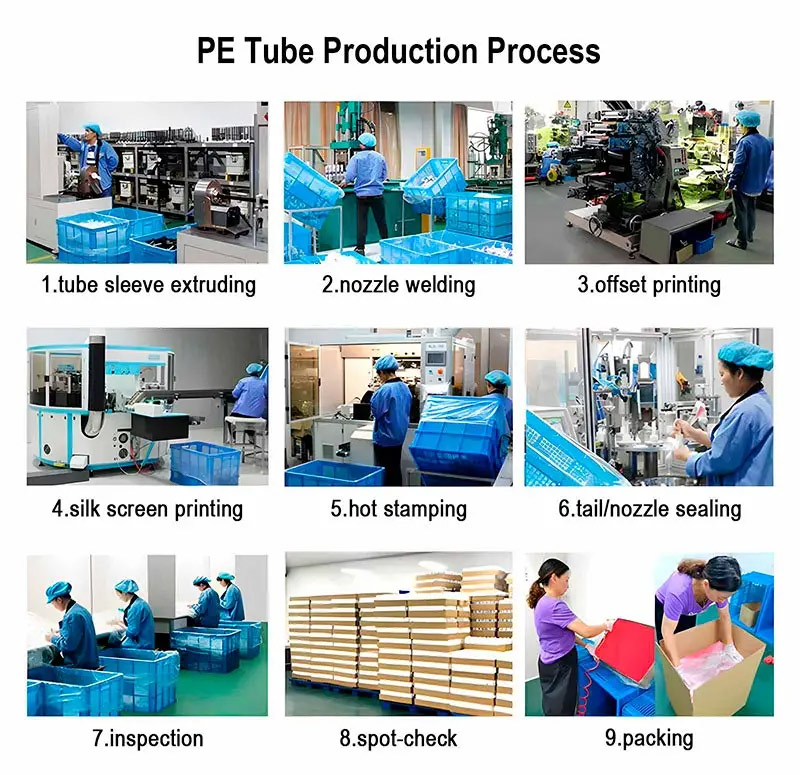

From Concept to Creation: The Runk Process

Our product development follows a detailed, systematic approach to ensure that every step is perfectly executed. Here’s a snapshot of our process:

♦ Sample Test

We start by confirming the product design with a sample test, ensuring that it meets your expectations.

♦ Cost Confirmation

Once the design is finalized, we work with you to confirm the cost for the batch production.

♦ Approval Stage

With PPS & RB approvals in place, we proceed to bulk production.

♦ Inspection

Each batch is rigorously inspected to ensure that the final product is of the highest quality.

♦ Shipping

After passing all checks, your customized packaging is ready for delivery, ensuring that it reaches you on time.

The Final Touch

Whether you're launching a new product or revamping an existing line, Runk's packaging is designed to enhance your brand image and provide a superior user experience. With customizable options, sustainable materials, and a commitment to quality, we’re the perfect partner for all your cosmetic packaging needs.

Contact Runk today to learn more about our innovative cosmetic packaging solutions!